Improving Industry 4.0 With Innovation Management

In today’s rapidly evolving business landscape, staying ahead of the competition requires embracing Industry 4.0 and leveraging the power and adaptability of Innovation Management and strategy. At Ezassi, we understand the importance of navigating sustainable innovation and have developed a range of solutions to help businesses thrive in this new era of digital transformation.

What is Industry 4.0 Innovation?

Industry 4.0 is the fourth industrial revolution, merging cutting-edge technologies with traditional manufacturing to create a smart and interconnected production ecosystem. It’s all about embracing automation, artificial intelligence, big data, and the Internet of Things to optimize productivity, efficiency, and innovation across the supply chain.

We are experiencing a new period of manufacturing excellence where machines communicate, analyze, and make decisions on their own, allowing businesses unprecedented growth and success. However, new robotics, improved data management systems, and impressive automation in a smart factory does not happen instantly, and substantial change management is required to prepare the workforce.

Industry 4.0 is a strategic approach across a variety of areas including:

- Additive Manufacturing

- Augmented reality

- Autonomous robots

- Big Data and analytics

- Cloud connectivity

- Cybersecurity

- Horizontal and vertical system integration

- The Internet of Things (IoT)

- Simulation and digital twins

Resources we suggest for a deeper understanding of what’s working in Industry and leaders in this revolution:

- The World Economic Forum’s Centre for Advanced Manufacturing and Supply Chains Global Lighthouse Network

- The International Centre for Industrial Transformation Smart Industry Readiness Index (SIRI), a framework to scale I4.0 across an organization

As an Innovation Management solution provider, Ezassi helps manufacturers initiate the innovation process by identifying specific Industry 4.0 manufacturing challenges which can be solved by a curated network of internal resources, external partnerships, and targeted subject matter experts. These challenges can range from research and development to production issues that are currently impeding progress. We then help evaluate, facilitate, and incentivize the key ideas formed by your solver ecosystem as part of the overall innovation process.

Let’s take a look at two use case examples.

Additive Manufacturing: New methods for Industry 4.0 Customized Production

In order to meet the demand for personalized products in Industry 4.0, innovative manufacturing methods must be developed. This is where AM, or Additive Manufacturing, can play a pivotal role as a cutting-edge technology capable of crafting bespoke items with remarkable attributes such as stronger materials and unique shapes. Also known as 3D printing, AM is a revolutionary technology that can greatly enhance the capabilities of a production facility. Industries including medical devices, biotech, aerospace, automotive, apparel, and food are finding applications for intricately designed, novel material customizations.

While conventionally used for prototyping, some manufacturers have achieved new age AM production of high quality, low volume end use parts through Direct Digital Manufacturing (DDM). Companies are successfully scaling additive manufacturing for mass customization; one relatable consumer apparel product example is from Adidas. With technology provided by Carbon, they created a high-tech sneaker sole for their Futurecraft 4D product line.

Integrating additive manufacturing becomes a challenge for a variety of siloed teams and departments. This includes engineers, designers, production managers, and other stakeholders who must work together to integrate AM into the production facility. Say an engineer sees an opportunity for redesigning a component using the latest in new materials and 3D printing capabilities. His or her idea must be recorded, reviewed, and promoted in a systemized process of non-siloed corporate ideation. Next, an R&D team may search for the best vendor to bring these capabilities to the facility. They’ll engage with subject matter experts from external sources for best practices. Scouting for novel technologies in this field and identifying the most suitable additive manufacturing solutions for the facility ensures that engineering stays up to date with the latest advancements in the field and production managers can make informed decisions regarding the adoption of new methods. Additionally, the design concept must be prototyped and tested for quality and performance. For this complex process to progress efficiently and transparently across the organization, the full project team must engage with a project pipeline of thoughtful discussion, knowledge sharing, and collaborative decision making.

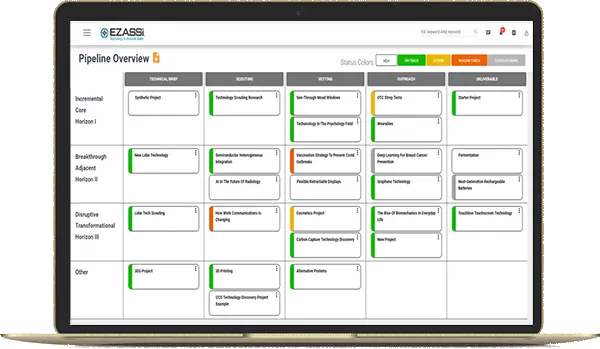

Ezassi Innovation Management Software advances project pipeline management. These products offer a configurable kanban system that allows teams to manage their innovation projects effectively. This includes tracking the progress of additive manufacturing initiatives, assigning tasks, and monitoring crucial timelines and workflows. The software acts as a central hub for communication and collaboration, enabling seamless coordination and digital documentation between these teams, expanding the innovative mindset of the organization. Our tools provide innovation KPIs to ensure that the implementation of AM remains on track and aligns with the facility’s overall innovation strategy. Leverage the benefits of this transformative technology within your manufacturing processes to innovate and incorporate Industry 4.0 capabilities.

Autonomous Robots: Increasing efficiency, quality, and speed in Pharmaceutical Manufacturing

Cobots, or collaborative robots, are becoming increasingly popular in various industries, including pharmaceutical manufacturing. These robots are designed to work alongside humans, assisting in tasks that require precision, speed, and productivity.

Consider Project MARVIN, a partnership project from Lonza, NIBRT, Novartis, UCD-LAMS and PM Group, as a case study in state-of-the-art mobile robotics assisting with environmental sampling in bioprocess environments. This robot moves freely through the laboratory, automating routine tasks of picking up, transporting, and scanning petri dishes. It integrates with an open web-based software system to collect environmental monitoring (EM) sample data quickly and reliably, thereby freeing up skilled laboratory researchers for other value-added activities. Robots are also advantageous to use in clean rooms as they are inherently less likely to bring contamination to a biomanufacturing environment as a human worker could.

How do organizations source new ideas for incorporating autonomous robots into their operations?

How can we better connect University researchers, corporate partners, and exciting start-ups in these collaborative, industry-changing innovations?

By leveraging technology scouting, pharmaceutical companies can stay updated with the latest advancements in cobots and implement these technologies within their manufacturing lines. Research and analysis of the landscape ensures that the robotic systems selected are equipped with the most advanced features and capabilities to further improve the efficiency and productivity of the manufacturing process. Ezassi serves as the research partner and innovation management platform to build these strategic collaborations with the robotics industry. Companies can also incorporate Ezassi’s Pipeline Management software to better track the innovation project pipeline from initial concept to installation to workforce training of advanced autonomous robots in an enhanced pharmaceutical manufacturing line.

In conclusion, Industry 4.0 presents immense opportunities for businesses to drive innovation and achieve sustainable growth. At Ezassi, we offer a range of software and services designed to empower organizations to fully embrace Industry 4.0 and realize the full potential of their manufacturing and supply chains.

Contact us today to continue your innovation journey through the fourth Industrial Revolution.

What are Ezassi Solutions?

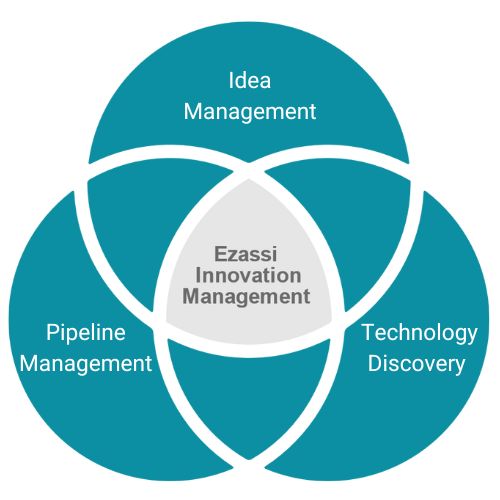

Our team of experts specializes in maximizing an organization’s innovation capabilities. Dedicated consultants collaborate closely with you to implement a tailored innovation program that perfectly aligns with your business objectives. With our cutting-edge software for idea management, technology discovery, and pipeline management, we champion your most ambitious innovation initiatives.

Our innovation engagements include:

- Guided Innovation:

We take the reins and manage the process for you.

With our expertise and experience, we guide you through the innovation journey, ensuring a smooth and efficient process. Our team of experts will work closely with you to understand your goals and objectives, and then develop a tailored innovation strategy.

- Collaborative Innovation:

We work hand in hand with your team to achieve shared goals.

Innovation is a collaborative effort, and we actively engage your team in the process with gamification and crucial KPI reporting, fostering a culture of innovation within your organization.

- Self-Service Innovation:

Empowering you with our intuitive SaaS tools to steer your innovation journey independently.

We provide intuitive Software-as-a-Service (SaaS) tools that empower you to drive innovation independently. Our self-service innovation platform allows you to collect and manage ideas, uncover emerging technologies, and manage your innovation projects efficiently.

Our Innovation Management technology includes:

Idea Management Software – platform for collecting and managing ideas

Our idea management software provides a centralized platform for capturing and organizing ideas from your team. It enables you to evaluate and prioritize ideas, facilitating effective decision-making and implementation.

Technology Discovery Software – scouting tool to uncover emerging technologies

Our technology discovery software helps you stay ahead of the curve by scouting for emerging technologies. It provides insights into the latest trends and innovations, allowing you to identify opportunities for growth and competitive advantage.

Pipeline Management Software – configurable kanban to manage your innovation projects

Our pipeline management software allows you to track progress, allocate resources, and ensure timely execution of your innovation initiatives.

Our Innovation Consulting Services include:

Foster corporate alignment, implement best practices, and establish KPIs to cultivate a culture of innovation and drive growth.

- We help you develop a comprehensive innovation strategy that aligns with your corporate goals and objectives.

- Our experts assist in implementing best practices and establishing key performance indicators (KPIs) to foster a culture of innovation and drive sustainable growth.

Technology Discovery and Market Analysis

Explore research initiatives intended to enhance and align with R&D and Engineering efforts.

- We conduct in-depth technology discovery and market analysis to identify research initiatives that expand your R&D and engineering efforts.

- By staying abreast of the latest technological advancements and market trends, we help you make informed decisions and stay competitive.

Implement a tailor-made innovation initiative that harmonizes seamlessly with your business objectives.

- Our Innovation Program Management Services ensure the successful implementation of your tailor-made innovation initiative.

- We work closely with your team to align the program with your business objectives, monitor progress, and provide ongoing support.